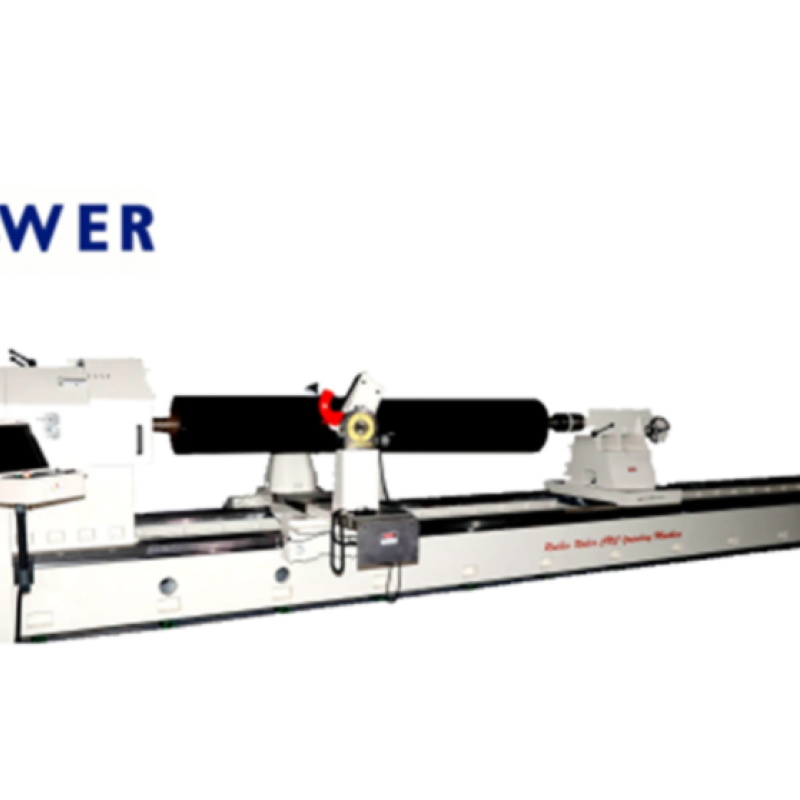

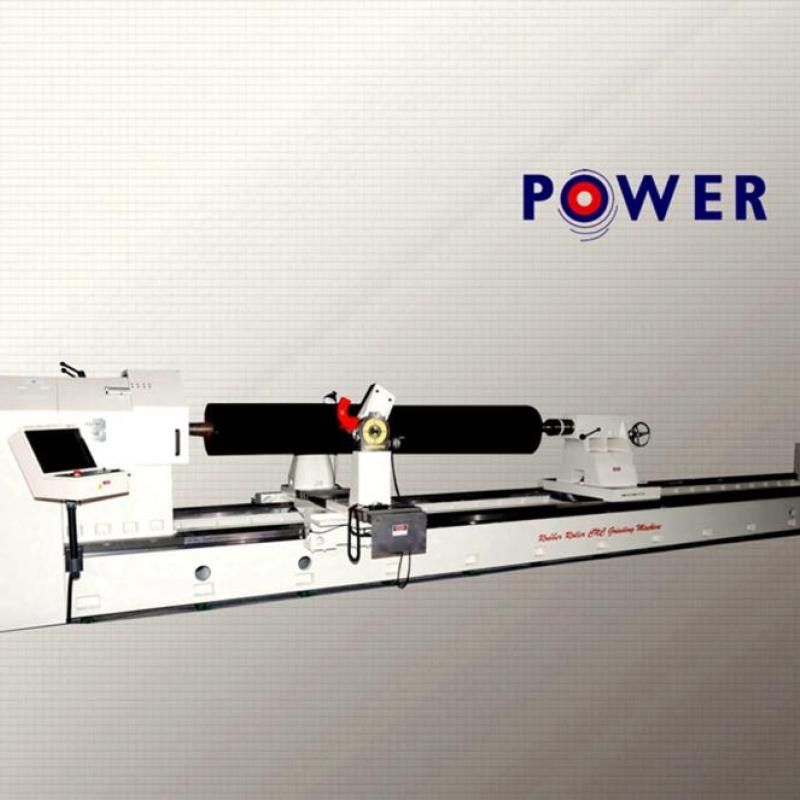

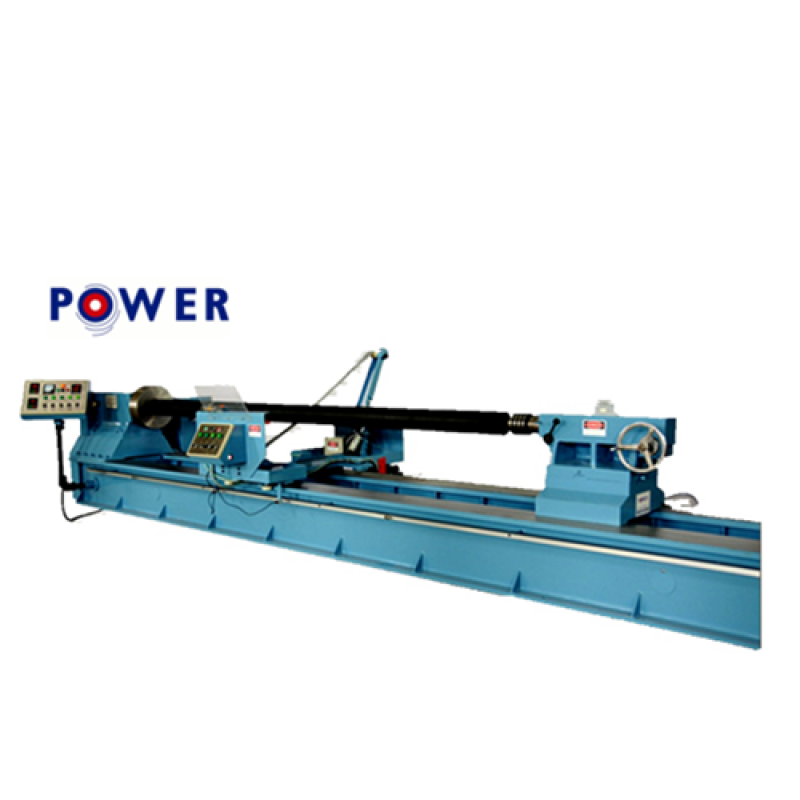

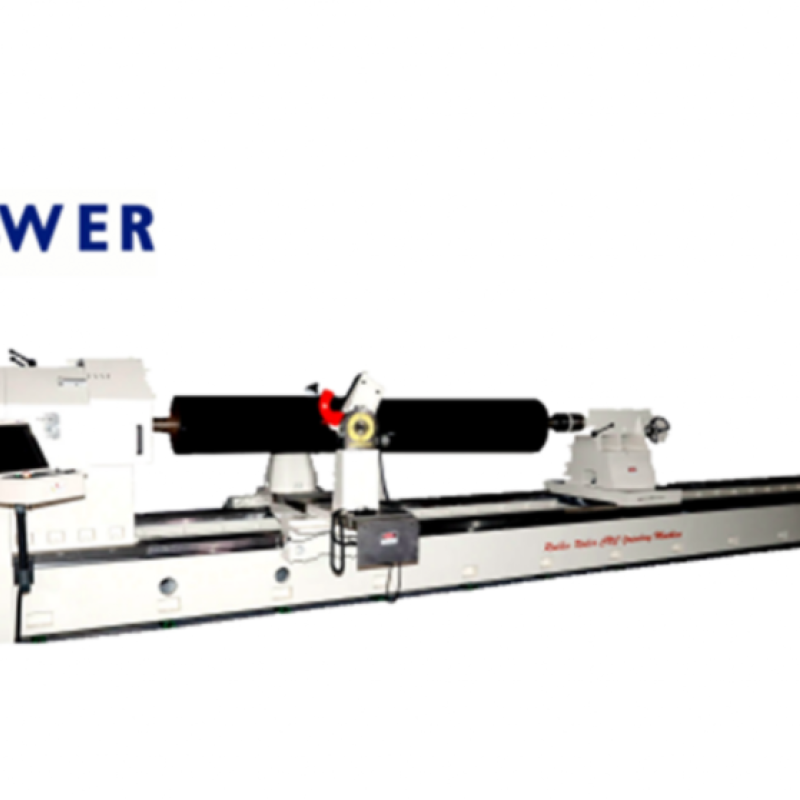

1. Factory customized rubber roller groover has our own developed user-friendly CNC operating system.2. The latest CNC system can easily operate more than 35 shapes on the rubber roller surface, which includes: crowning, concave,and wave grindings; herringbone, diamond, straight groovings, etc. 3. Remote problem solving function availabe.4. Having all the functions of our PSM series general grinding machine.Due to the all-round of the system function, factory customized rubber roller groover can make almost all the profile of rollers.

Contact Now

1. factory customized rubber roller groover has our personal developed user-pleasant cnc operating system.2. the contemporary cnc gadget can without problems perform more than 35 shapes on the rubber roller floor, which incorporates: crowning, concave,and wave grindings; herringbone, diamond, directly groovings, and many others. 3. far off problem fixing feature availabe.4.

Contact Now

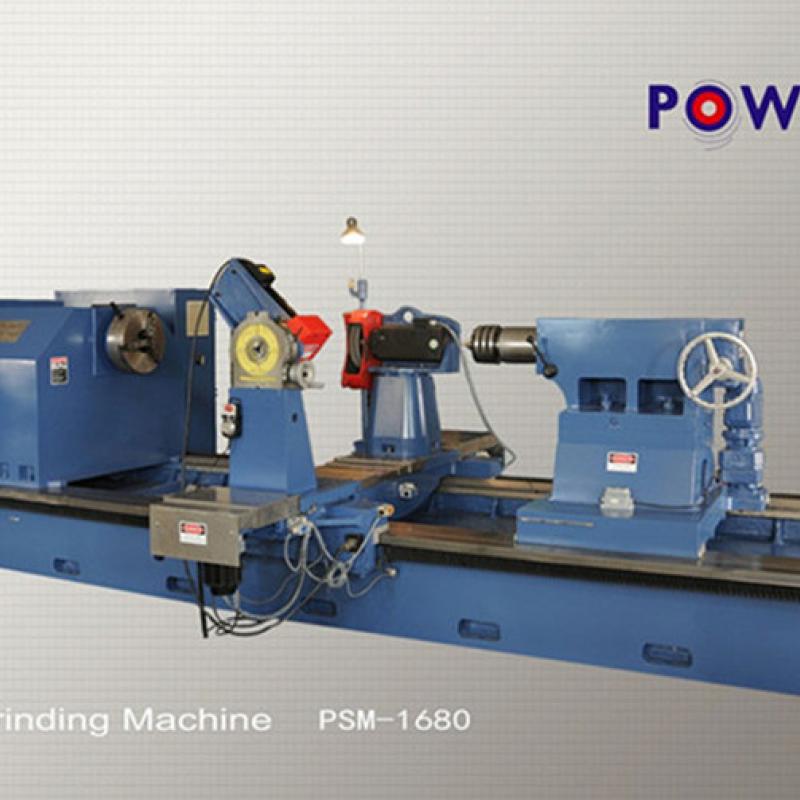

The feature of PSM series Jinan Rubber Roller CNC Roll Grinding MachineDue to the all-spherical of the machine function, manufacturing unit custom designed rubber curler groover could make nearly all of the profile of rollers. For instance, parabolic crowning and concave, cosine crowning and concave, circular, cone, coarse pitch, herringbone, diamond, instantly groove, horizontal groove and different formations withinside the appended drawing.1. Standard equipment of PSM series includes: a. a full flood recirculating coolant system b.

Contact Now

Because of the all-round of the device characteristic, manufacturing unit customized rubber curler groover should make nearly all the profile of rollers. as an instance, parabolic crowning and concave, cosine crowning and concave, circular, cone, coarse pitch, herringbone, diamond, right now groove, horizontal groove and different formations inside the appended drawing.1.

Contact Now

1. Factory customized rubber roller groover has our own developed user-friendly CNC operating system.2. The latest CNC system can easily operate more than 35 shapes on the rubber roller surface, which includes: crowning, concave,and wave grindings; herringbone, diamond, straight groovings, etc. 3. Remote problem solving function availabe.4. Having all the functions of our PSM series general grinding machine.Due to the all-round of the system function, factory customized rubber roller groover can make almost all the profile of rollers.

Contact Now

Due to the all-round of the system function, factory customized rubber roller groover can make almost all the profile of rollers. For instance, parabolic crowning and concave, cosine crowning and concave, circular, cone, coarse pitch, herringbone, diamond, straight groove, horizontal groove and other formations in the appended drawing.1.

Contact Now

PSM-1680-CNC Rubber Roller Groover / Grooving / Grinder / Grinding MachinesDue to the all-round of the system function, it can make almost all the profile of rollers.

Contact Now

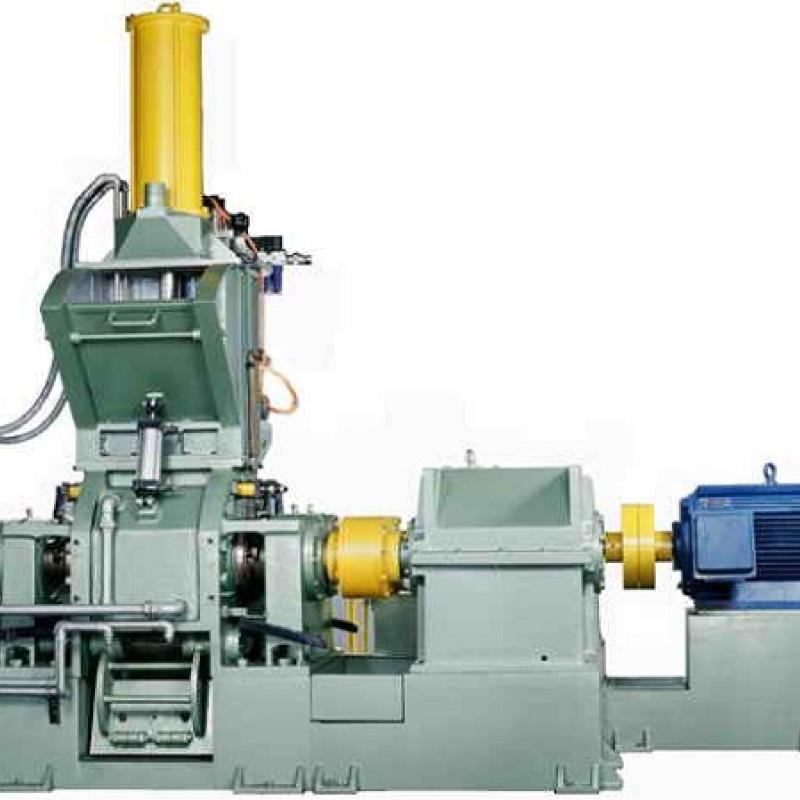

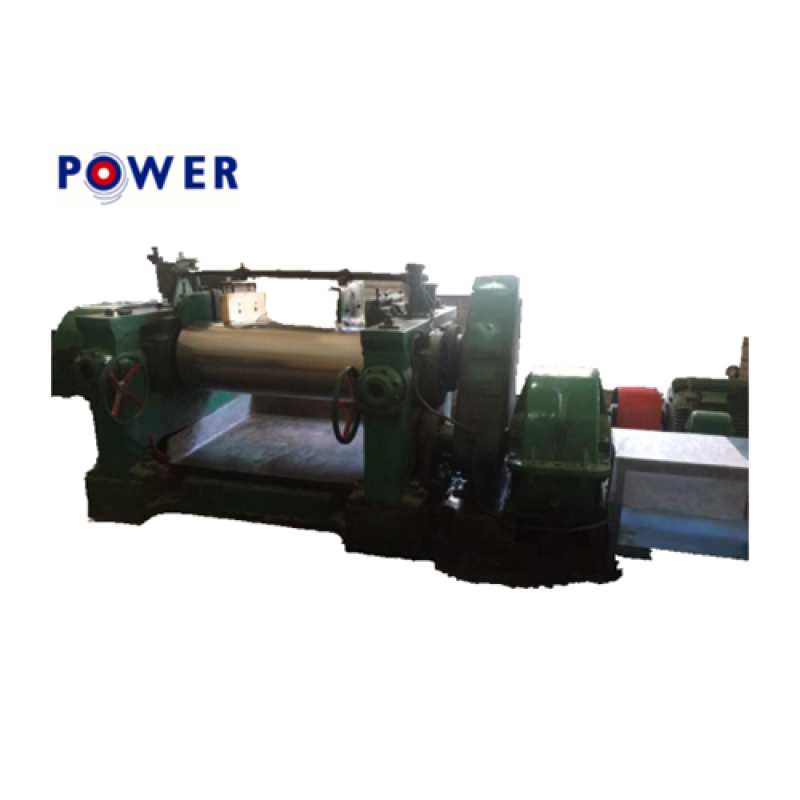

Banbury Rubber mixer machineThe scope application of internal mixer is very wide, such as rubber, synthetic rubber, resin, asphalt, cellulose,P.V.C.E.V.A. raw materials such as P.E, can in the shortest time to complete mixing. The Rubber banbury internal mixer machine body structure is strong and durable. The powder stop equipment can effectively prevent the leakage of raw materials and compound agents through special design. It has long service life, simple operation, good effect and easy maintenance, and it is also very convenient to replace the worn parts.

Contact Now

Banbury Rubber machineBanbury Rubber machine is a kind of high strength clearance mixing equipment developed on the basis of the open mixer milll.Therefore, the emergence of Banbury Rubber machine is a rubber machinery, an important achievement, still is the plastic refining and mixing of the typical important equipment, is still in constant development and improvement. Our Services1.Installation service.2.Maintenance service.3.Technical support online service provided.4.Technical files service provided.5.On-site training service provided.6.Spare parts replacement and repair ser

Contact Now

Banbury Rubber machineBanbury rubber device is a type of high electricity clearance mixing device evolved on the premise of the open mixer milll.consequently, the emergence of banbury rubber machine is a rubber machinery, an vital achievement, nevertheless is the plastic refining and mixing of the everyday critical equipment, continues to be in consistent improvement and improvement. Our Services1.Installation service.2.Maintenance service.3.Technical support online service provided.4.Technical files service provided.5.On-site training service provided.6.Spare parts replacement and repair

Contact Now

Product Description:1. Enhance the intensity of the rubber open mixer machine body by using more carbon steel and less wrought iron.2. The rubber open mixing mill can be placed on the plain ground directly, other installation method is unnecessary.3. The roller bearing supports the heavy loading and high temperature.

Contact Now

Product Description:1. Enhance the intensity of the rubber open mixer machine body by using more carbon steel and less wrought iron.2. The rubber open mixing mill can be placed on the plain ground directly, other installation method is unnecessary.3. The roller bearing supports the heavy loading and high temperature.

Contact Now

Product Description:1. Enhance the intensity of the machine body by using more carbon steel and less wrought iron.2. Machine can be placed on the plain ground directly, other installation method is unnecessary.3. The roller bearing supports the heavy loading and high temperature.

Contact Now

Product description1. this gadget is designed as a follow up device of our psm collection for the rubber roller floor refining device.2. assembly critical requirements on the ground smoothness thru selecting the abrasive band with specific granularity.3. the geometric length of rubber roller will stay unchanged.Four. the running device is simple and smooth-to-use.MODELSPECIFICATIONMAX. DIAMETERMAX.

Contact Now

About usJinan Power Rubber Roller Equipment Co., Ltd is a modern private enterprise embodying scientific research and production. It was set up in 1998, and now is the main base in our country for manufacturing rubber roller special machine.Power Company is a professional producer engaged in rubber roller manufacturing equipment, with a large production scale and strong technical force.

Contact Now

PSF rubber roller surface measuring instrument is specially designed and manufactured for rubber roller production enterprises. It's a kind of precise testing instrument consist of the most advanced laser probe. It can make measurement for any apparent tolerance and roughness on surface of rubber rollers.

Contact Now

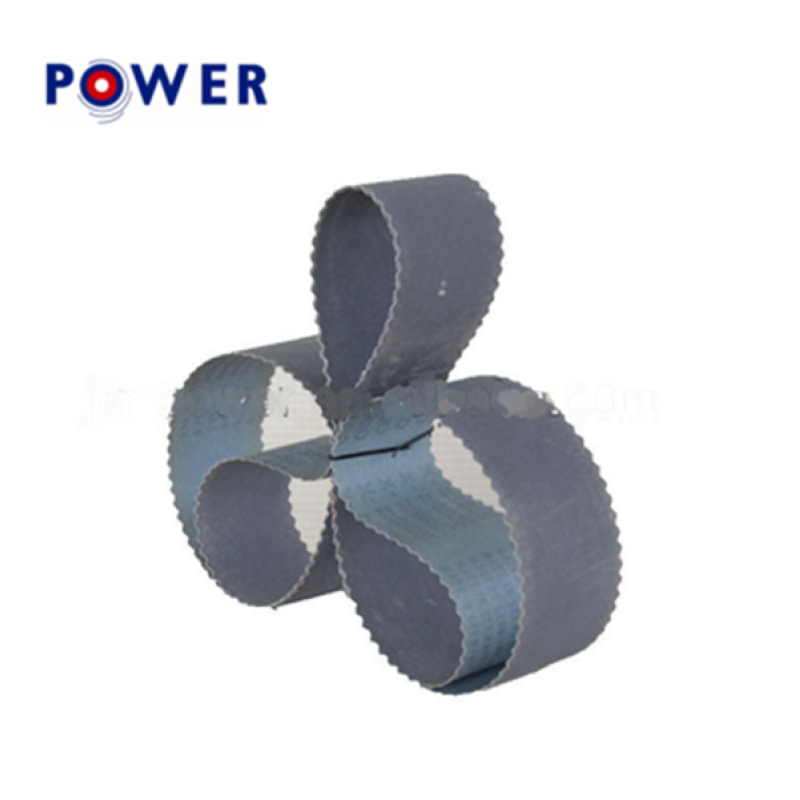

Product descriptionCharacteristic:1. can be used for water throwing and dry throwing;2. rubber belt polishing and roll center dehairing belt;3. there are more than one types, length and stylePackaging detail: 1. Outside package: Standard export wooden cases.2. Inner package: Stretch film.Shipping detail: Within 2-4 weekOur Services1.Installation service.2.Maintenance service.3.Technical support online service provided.4.Technical files service provided.5.On-site training service provided.6.Renew service provided.Product use:Shipping photos:

Contact Now

With the tenet of quality first, clients the highest, Power Company provides to you all-round services of rubber rollers, e.g., re-rubbering of shabby rubber rollers, mapping and manufacture of new base gum and corollary services for equipment manufacturers.Web Press Rubber Roller For PrinterPower Company adopts various special glue stock made in USA and Germany to manufacture industrial robber rollers. For printing industry, there are alcohol plate moisturizing rubber roller, UV inker, rubber roller transmitting and sparing ink.

Contact Now

Product descriptionCharacteristic:1.can be used for water throwing and dry throwing;2. rubber belt polishing and roll center dehairing belt;3. there are more than one types, length and stylePackaging detail: Outside package: Standard export wooden cases.Inner package: Stretch film.Shipping detail: Within 2-4 weekOur ServicesInstallation service.Maintenance service.Technical support online service provided.Technical files service provided.On-site training service provided.Renew service provided.Product use:Shipping photos:

Contact Now

PSF rubber roller surface measuring instrument is specially designed and manufactured for rubber roller production enterprises. It's a kind of precise testing instrument consist of the most advanced laser probe. It can make measurement for any apparent tolerance and roughness on surface of rubber rollers.

Contact Now

1. Factory custom designed rubber curler groover has our personal advanced user-pleasant CNC running gadget.2. The modern CNC gadget can without difficulty perform extra than 35 shapes at the rubber curler surface, which includes: crowning, concave,and wave grindings; herringbone, diamond, immediately groovings, etc. 3. Remote trouble fixing characteristic availabe.4. Having all of the capabilities of our PSM collection preferred grinding machineDue to the all-round of the system function, factory customized rubber roller groover can make almost all the profile of rollers.

Contact Now

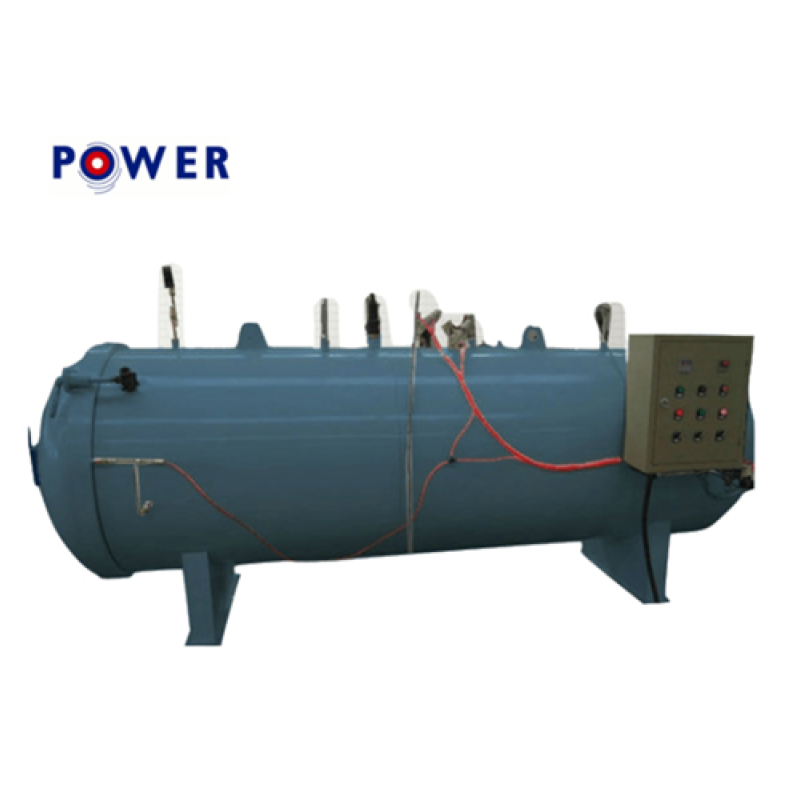

Roller Boiler Standerand Configurations: -Diameter 1500 * Length 4000 mm -Material: Q345R -Thickness of the vulcanizer: 8mm -Thickness of the end enclosure: 8mm -Designed pressure: 0.85mpa -Designed temperature: 180C -Automatic heating vulcanizer, temperature, pressure, and heating time, are controled by computer.

Contact Now

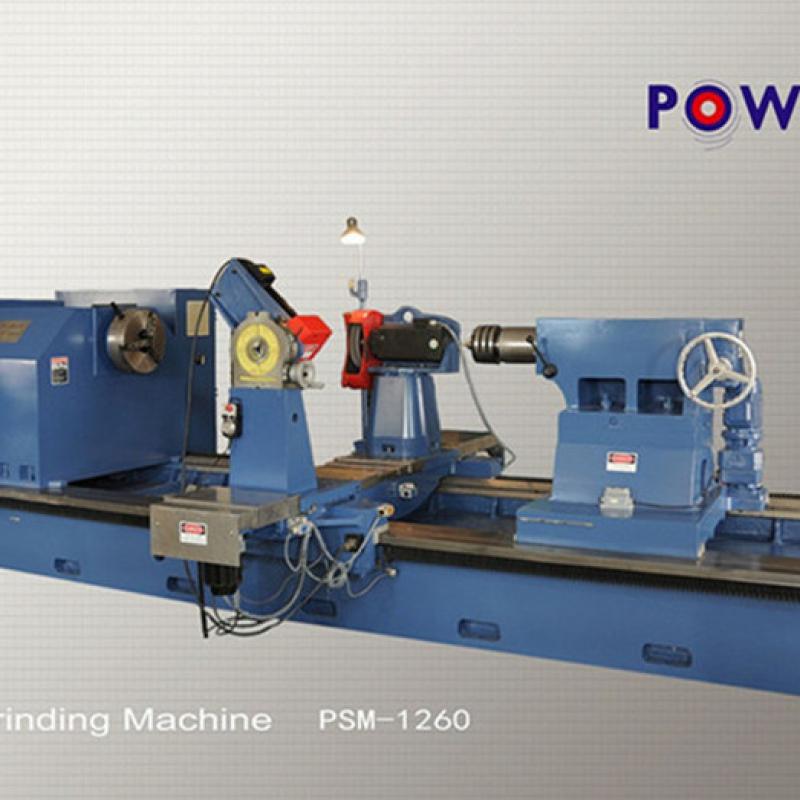

Grinding Machine for Rubber Roller MakingThe feature of PSM series Grinding Machine for Rubber Roller MakingPSM series Factory Automatic Cylindrical Roll Grinder is specially designed and manufactured to replace the past roller processing method by metallic manufacturing equipment. Mounted grinding head on the engine lathe is the past method to manufacture roller, which the quality of roller is difficult to reach the requirement of the present standard. The main reason lies in the structure of lathe.

Contact Now

1.especially designed with the useful resource of strength for particular first-rate manage of rubber rollers.2. inclusive of the maximum advanced laser probe. making dimension for any obvious tolerance and roughness on floor of rubber rollers.3. connecting to pc effortlessly for facts's transmission and evaluation.4. consumer first-class working device.PSF rubber roller surface measuring instrument is specially designed and manufactured for rubber roller production enterprises. It's a kind of precise testing instrument consist of the most advanced laser probe.

Contact Now