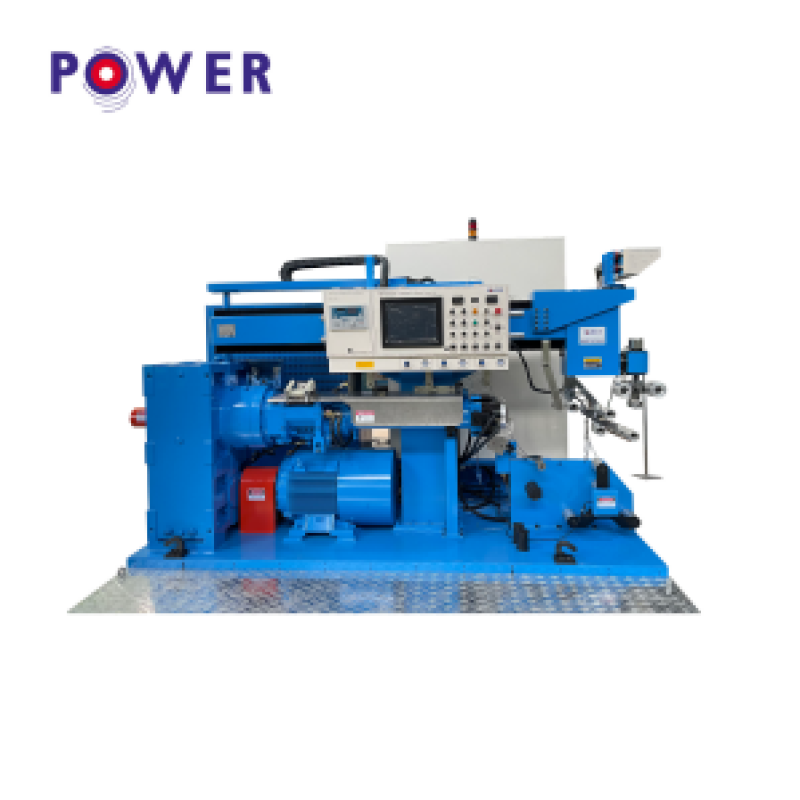

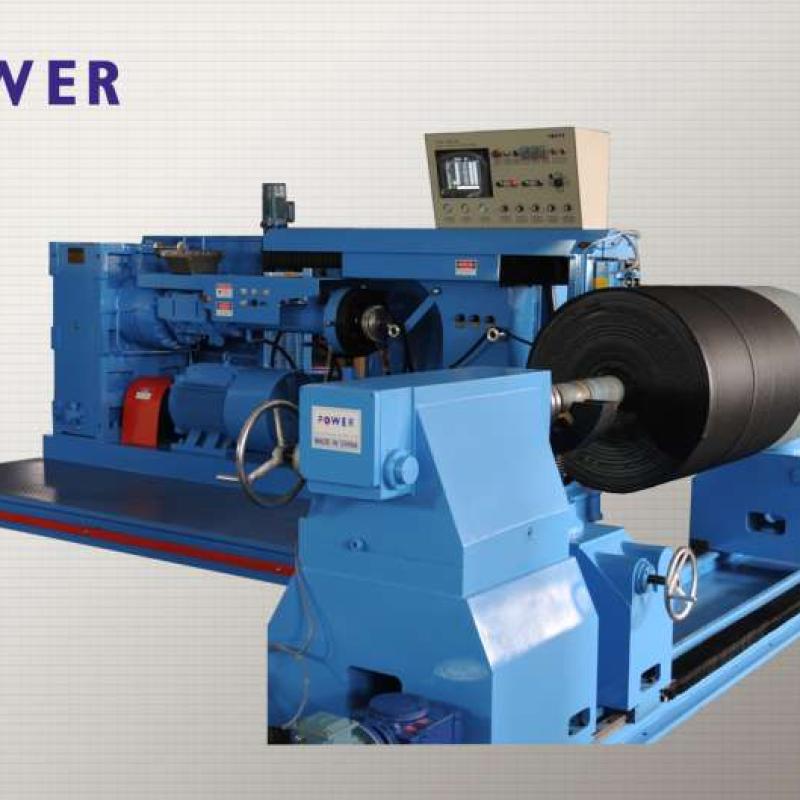

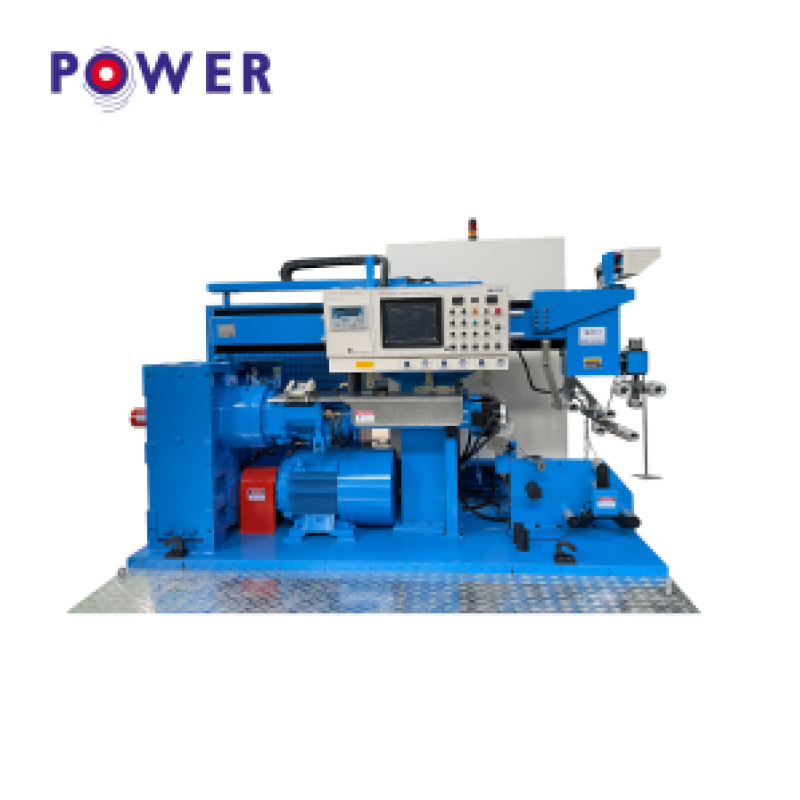

Product descriptionFeatures of PTM-8060 Rubber Roller Coating Machine Price1.Applicable to production of Rubber Rollers in heavy industry, such as transmission rubber rollers in steel and steel deepprocessing industry,textile industry,printing and dyeing industry and so on.2.Equipped with E300CS 76 cold feed extruder designed by POWER and a complete industrial refrigeration system.3.Applicable to rubber compounding with all hardness.4.Optional expansion covering function for special parts of the rubber rollers.5.Capable of producing 40-60 printing rubber rollers per shift generallyPT

Contact Now

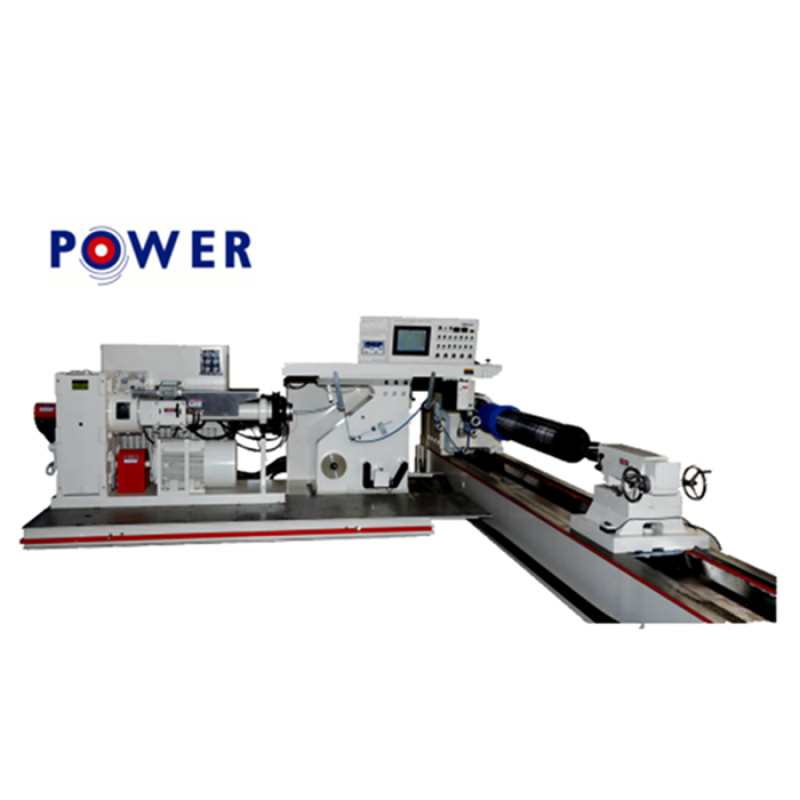

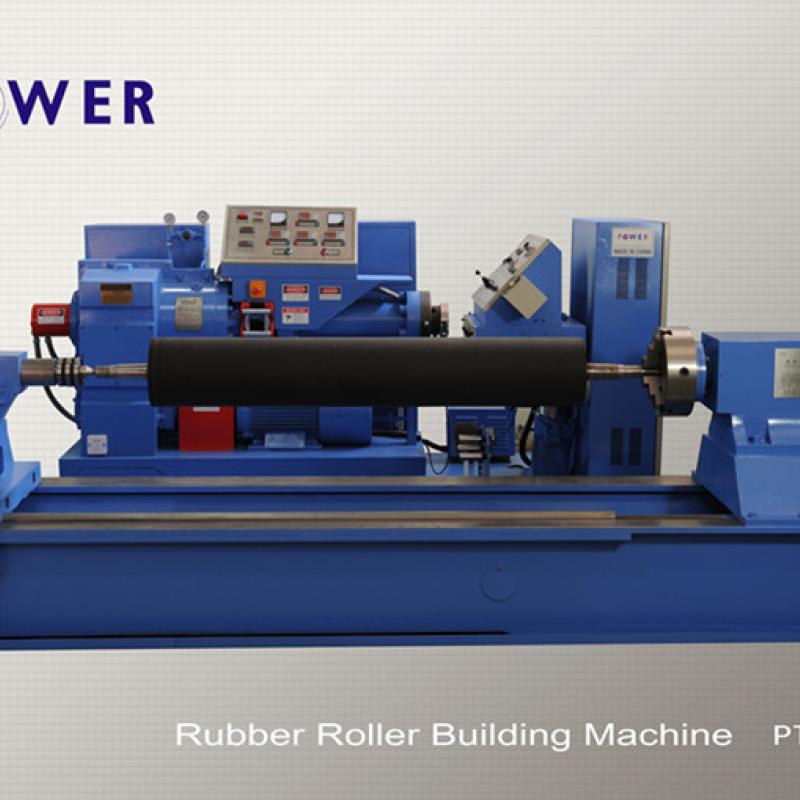

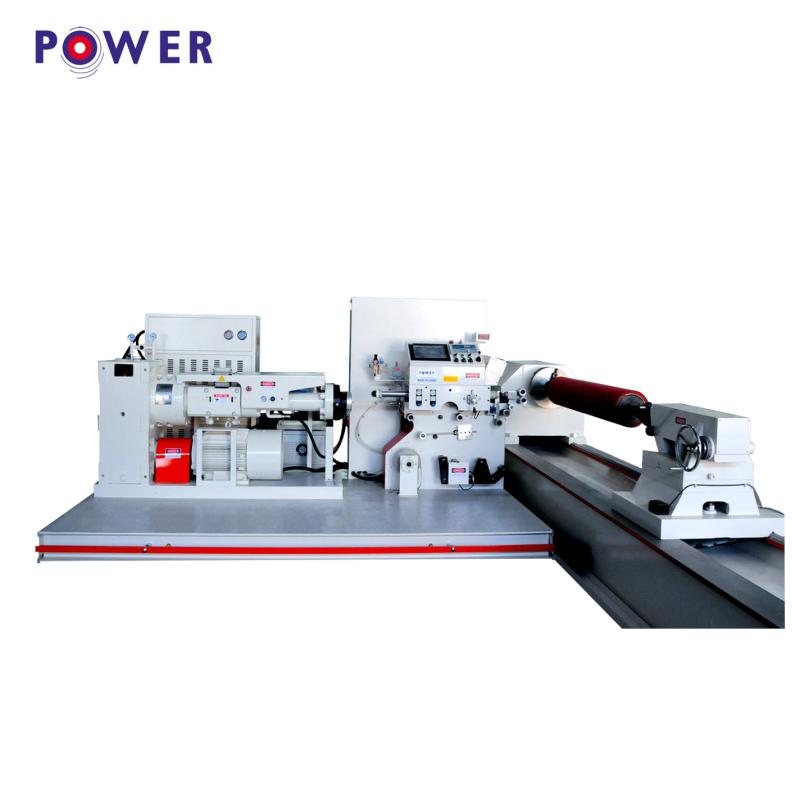

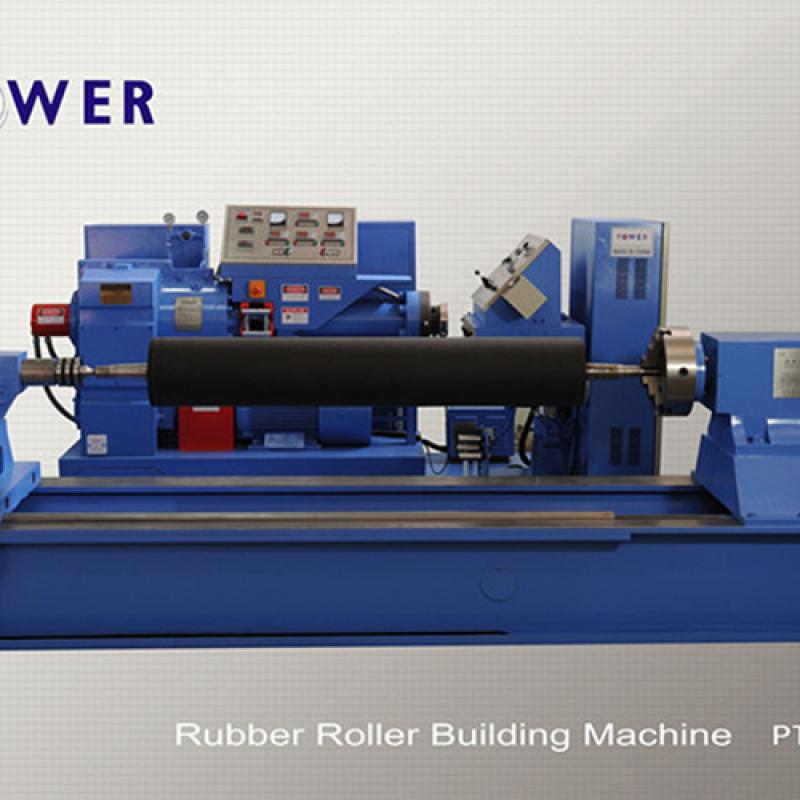

Product descriptionFeatures of PTM-1080 Steel Textile Dyeing Rubber Roller Wrapping Machine1. Rubber roller building machine PTM-1080 model is suitable for processing industrial rolls such as steel mill rolls, textile rolls and dyeing rolls.2. Our rubber roller building machine equipped with E300CS power extruder and a complete industrial cooling system.3. The rubber roller building machine is applicable to rubber compounding with all hardness range 15-100A.4. The Covering Machine is easy Installation with our professional technical support.5.

Contact Now

Product descriptionFeatures of PTM-4030 Rubber Roller Coating Machine1.Applicable to production of printing Rubber Rollers and general rubber roller.2.Equipped with E250CS cold feed extruder designed by POWER and a complete industrial refrigeration system.3.Applicable to rubber compounding with hardness The hardness range is 15-100A.4.Optional expansion covering function for special parts of the rubber rollers.5.Capable of producing 40-60 printing rubber rollers per shift generallyPTM Series Rubber Roller Coating MachineThe automatic rubber roller Covering Machine is d

Contact Now

Product description1.Rubber roller building machine PTM-1080 model is suitable for processing industrial rolls such as steel mill rolls, textile rolls and dyeing rolls.2. Our rubber roller building machine equipped with E300CS power extruder and a complete industrial cooling system.3. The rubber roller building machine is applicable to rubber compounding with all hardness range 15-100A.4. The covering machine is easy Installation with our professional technical support.5.

Contact Now

Product description1.Rubber roller building machine PTM-1080 model is suitable for processing industrial rolls such as steel mill rolls, textile rolls and dyeing rolls.2. Our rubber roller building machine equipped with E300CS power extruder and a complete industrial cooling system.3. The rubber roller building machine is applicable to rubber compounding with all hardness range 15-100A.4. The covering machine is easy Installation with our professional technical support.5.

Contact Now

Product descriptionFeatures of PTM-4030 Rubber Roller Coating Machine1.Applicable to production of printing Rubber Rollers and general rubber roller.2.Equipped with E250CS cold feed extruder designed by POWER and a complete industrial refrigeration system.3.Applicable to rubber compounding with hardness The hardness range is 15-100A.4.Optional expansion covering function for special parts of the rubber rollers.5.Capable of producing 40-60 printing rubber rollers per shift generallyPTM Series Rubber Roller Coating MachineThe automatic rubber roller Covering Machine is d

Contact Now

Product descriptionThe NBR Rubber Roller Covering Machine Hot Sale is designed and produced for improving the rubber covering process.

Contact Now

Product Description:1. Enhance the intensity of the Open Mill machine body by using more carbon steel and less wrought iron.2. The rubber open mixer machine can be placed on the plain ground directly, other installation method is unnecessary.3. The roller bearing supports the heavy loading and high temperature.

Contact Now

PSF rubber roller surface measuring instrument is specially designed and manufactured for rubber roller production enterprises. It's a kind of precise testing instrument consist of the most advanced laser probe. It can make measurement for any apparent tolerance and roughness on surface of rubber rollers.

Contact Now

Product description1. the pcm-8040 model is appropriate for renewing commercial rubber rollers.2. eliminating antique rubber by using special ring cutter.Three. replacing the conventional sand-blasting and solvent washing technique by way of superior belt-grinding system.Four. flawlessly retaining the unique dynamic balance of the roller core.Five. giving more reliable assure for the bonding of the rubber and steel cores.6. saving expenses and labors with this stepped forward manufacturing machine.MODELSPECIFICATIONMAX. DIAMETERMAX.

Contact Now

PSM-8040 General Rubber Roller Surface Grinding MachinePSM collection rubber curler grinding gadget is mainly designed and synthetic to replace the beyond roller processing approach by using way of steel production device. installation grinding head on the engine lathe is the past technique to fabricate curler, which the first-rate of curler is difficult to gain the requirement of the prevailing full-size. the primary purpose lies within the form of lathe.

Contact Now

Product descriptionFeatures of PTM-2012 Rubber Roller Wrapping Machine For Mining Transmission1. Rubber curler Covering Machine PTM-2012 version is appropriate for processing paper mill, mine transportation and heavy commercial rolls.2. Our rubber curler constructing system prepared with E350CS energy extruder and a whole commercial cooling system.3. The Rubber Roller Covering Machine is relevant to rubber compounding with all hardness variety 15-100A.4. The masking system is simple Installation with our expert technical support.5.

Contact Now

Product Description:1. Enhance the intensity of the machine body by using more carbon steel and less wrought iron.2. Machine can be placed on the plain ground directly, other installation method is unnecessary.3. The roller bearing supports the heavy loading and high temperature.

Contact Now

Product Description:1. Enhance the intensity of the Open Mill machine body by using more carbon steel and less wrought iron.2. The rubber open mixer machine can be placed on the plain ground directly, other installation method is unnecessary.3. The roller bearing supports the heavy loading and high temperature.

Contact Now

Product descriptionFeatures of PTM-2012 Rubber Roller Wrapping Machine For Mining Transmission1. Rubber roller Covering Machine PTM-2012 model is suitable for processing paper mill, mine transportation and heavy industrial rolls.2. Our rubber roller building machine equipped with E350CS power extruder and a complete industrial cooling system.3. The Rubber Roller Covering Machine is applicable to rubber compounding with all hardness range 15-100A.4. The covering machine is easy Installation with our professional technical support.5.

Contact Now

PSM-4020 General Rubber Roller Surface Grinding MachinePSM series rubber roller grinding system is in particular designed and artificial to update the past roller processing technique with the aid of using manner of steel manufacturing equipment. installation grinding head on the engine lathe is the past technique to manufacture curler, which the superb of curler is tough to gain the requirement of the existing widespread. the number one reason lies withinside the form of lathe.

Contact Now

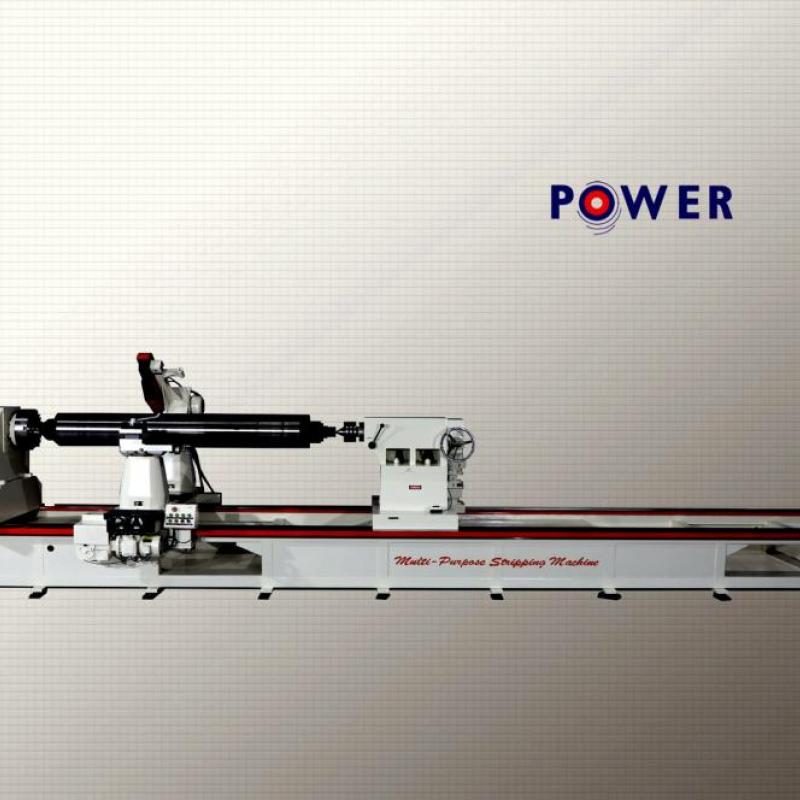

PCM Multi-Purpose Stripping Machine is eparticularly researched, evolved and designed for treating vintage Rubber Rollers. PCM Multi-cause Stripping Machine has the benefits that: Old rubber may be quick eliminated through a unique ring cutter, a curler middle could have a brand-new floor beneathneath the unique belt grinding mode. Adhesive brushing and drying are facilitated, bonding of rubber and the curler middle is ensured, which changed the conventional sand blasting process.

Contact Now

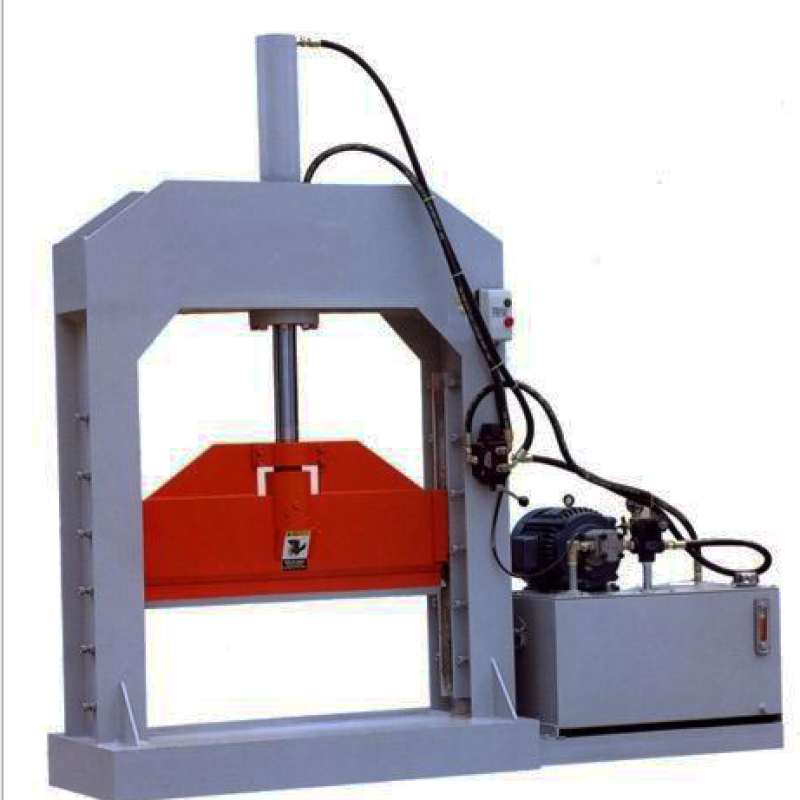

The Hydraulic rubber cutting machine The Hydraulic rubber cutting machine mainly has the cutting glue knife, the machine frame, the work oil cylinder, the base, the auxiliary work table and the hydraulic system, the electrical system and so on part composes, the cutting glue knife base is equipped with the nylon or the soft lead backing plate, protects the cutting knife the blade.Raw gum, with artificial glue in the cutting knife below, and then press the Start button, then the cutting knife in the piston rod driven by the slide along the rack down the rubber material cut.The ra

Contact Now

Product Description:1. Enhance the intensity of the machine body by using more carbon steel and less wrought iron.2. Machine can be placed on the plain ground directly, other installation method is unnecessary.3. The roller bearing supports the heavy loading and high temperature.

Contact Now

Product description1. The PCM-4030 model is suitable for renewing printing rollers, general industrial rollers and small Industrial Rubber Rollers.2. Removing old rubber by special ring cutter.3. Replacing the traditional sand-blasting and solvent washing process by advanced belt-grinding process.4. Perfectly keeping the original dynamic balance of the roller core.5. Giving more reliable guarantee for the bonding of the rubber and steel cores.6. Saving costs and labors with this improved production system.MODELSPECIFICATIONMAX. DIAMETERMAX.

Contact Now

Product Description:1. Enhance the intensity of the rubber open mixer machine body by using more carbon steel and less wrought iron.2. The rubber open mixing mill can be placed on the plain ground directly, other installation method is unnecessary.3. The roller bearing supports the heavy loading and high temperature.

Contact Now

Product Description:1. Enhance the intensity of the rubber open mixer machine body by using more carbon steel and less wrought iron.2. The rubber open mixing mill can be placed on the plain ground directly, other installation method is unnecessary.3. The roller bearing supports the heavy loading and high temperature.

Contact Now

Product description1. The PCM-1250 model is suitable for renewing Industrial Rubber Rollers.2. Removing old rubber by special ring cutter.3. Replacing the traditional sand-blasting and solvent washing process by advanced belt-grinding process.4. Perfectly keeping the original dynamic balance of the roller core.5. Giving more reliable guarantee for the bonding of the rubber and steel cores.6. Saving costs and labors with this improved production system. MODELSPECIFICATIONMAX. DIAMETERMAX.

Contact Now

PSM collection rubber roller grinding system is especially designed and artificial to replace the past curler processing method through the use of way of steel manufacturing device. set up grinding head on the engine lathe is the beyond approach to fabricate curler, which the great of roller is difficult to benefit the requirement of the prevailing giant. the number one purpose lies within the form of lathe. ultimately, it isn't always the grinding device; the transferring areas of the massive and medium carriage desk are huge than that of grinding tool.

Contact Now